API Casing and Tubing

Tubulars

pipe, well completion

Well casing and tubing is an integral part of the oil drilling and completion process.

API Casing and Tubing

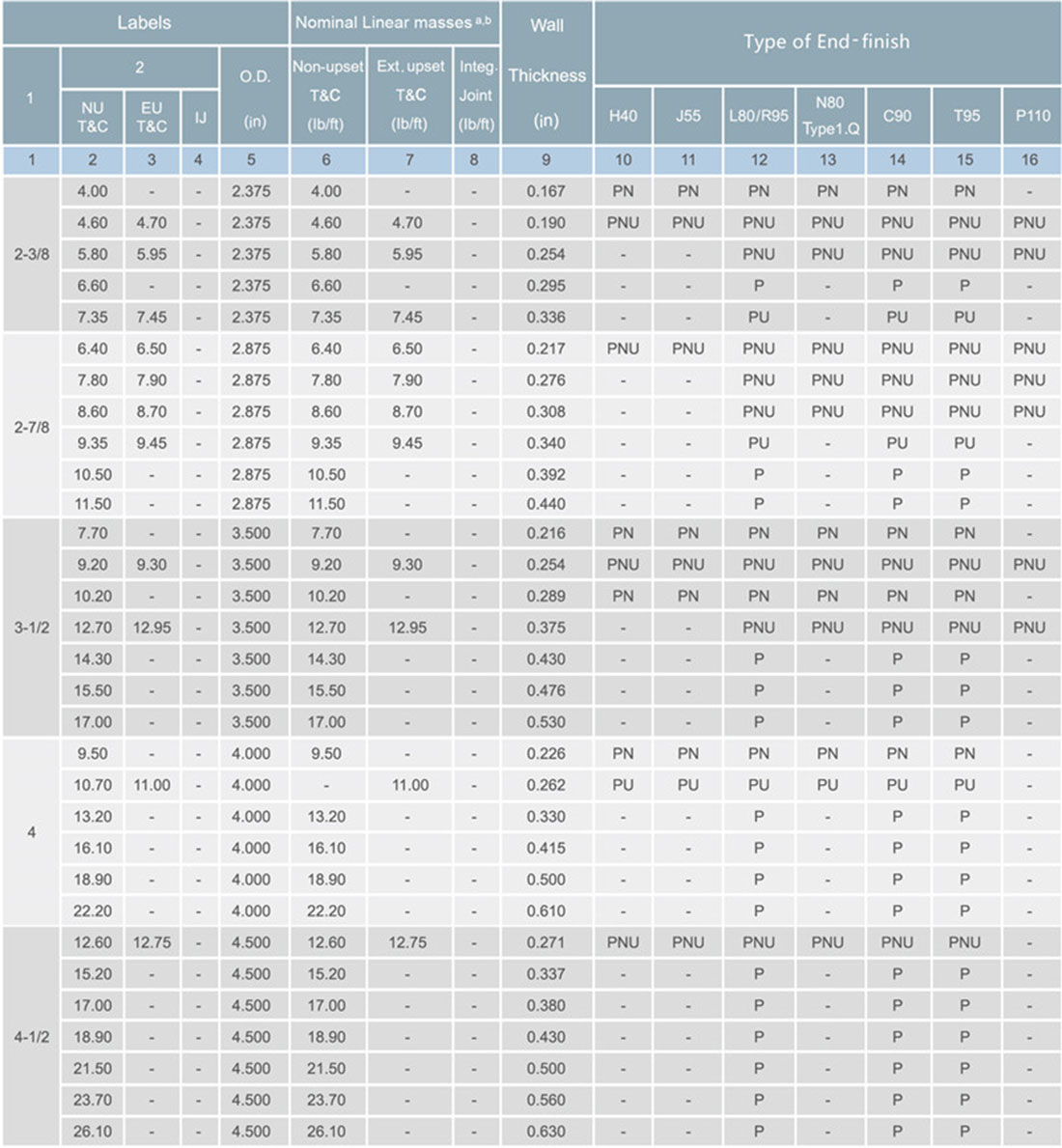

API Casing

In general, casing provides structure and strength to the walls of the well hole so that it doesn’t collapse on itself. It also ensures that there is no seepage of oil or natural gas out of the well hole as these are brought to the surface.

a: Buttress casing is available with regular, special clearance couplings or special clearance couplings with special bevel.

P= Plain end; S= Short round thread; L= Long round thread; B= Buttress thread.

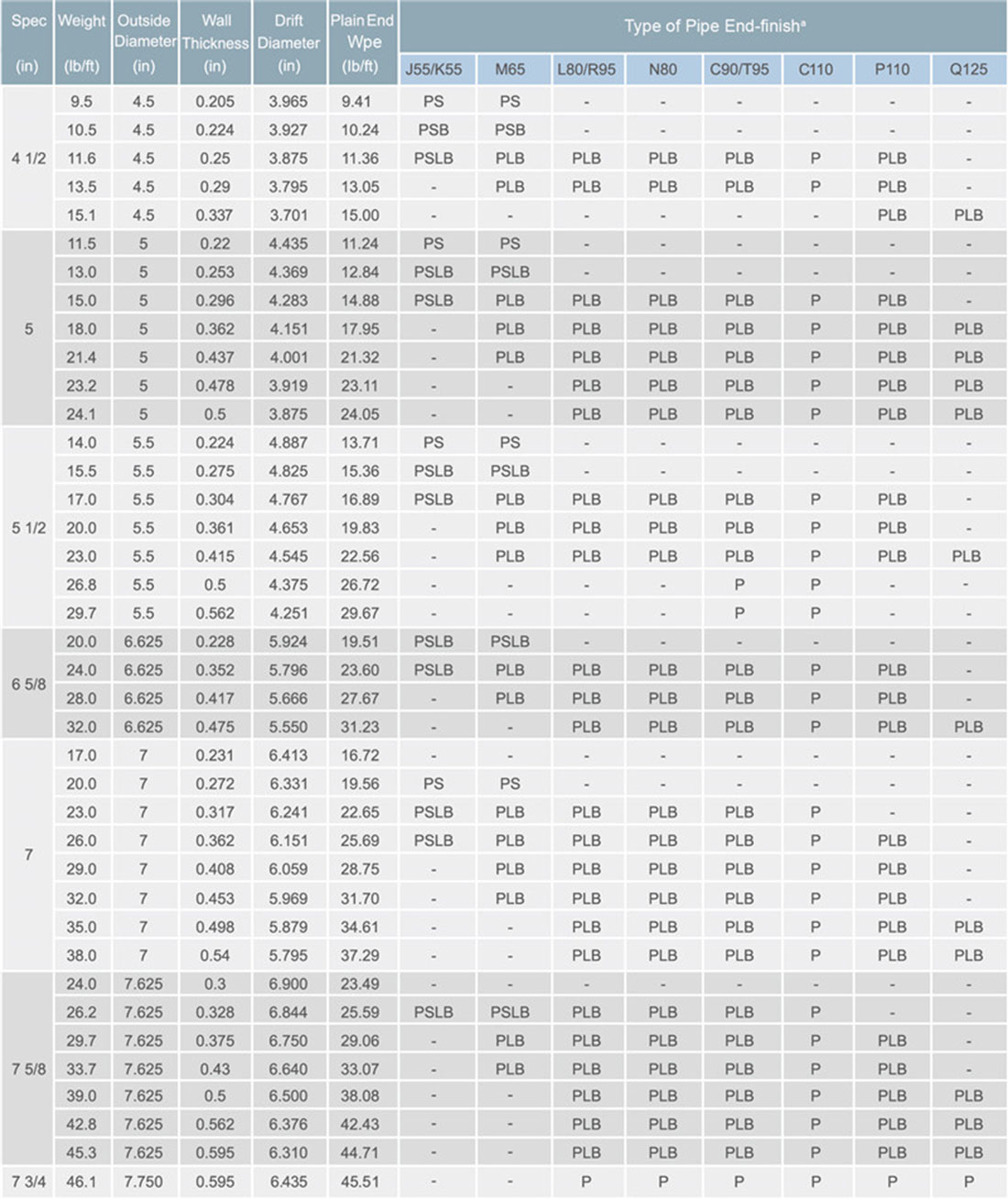

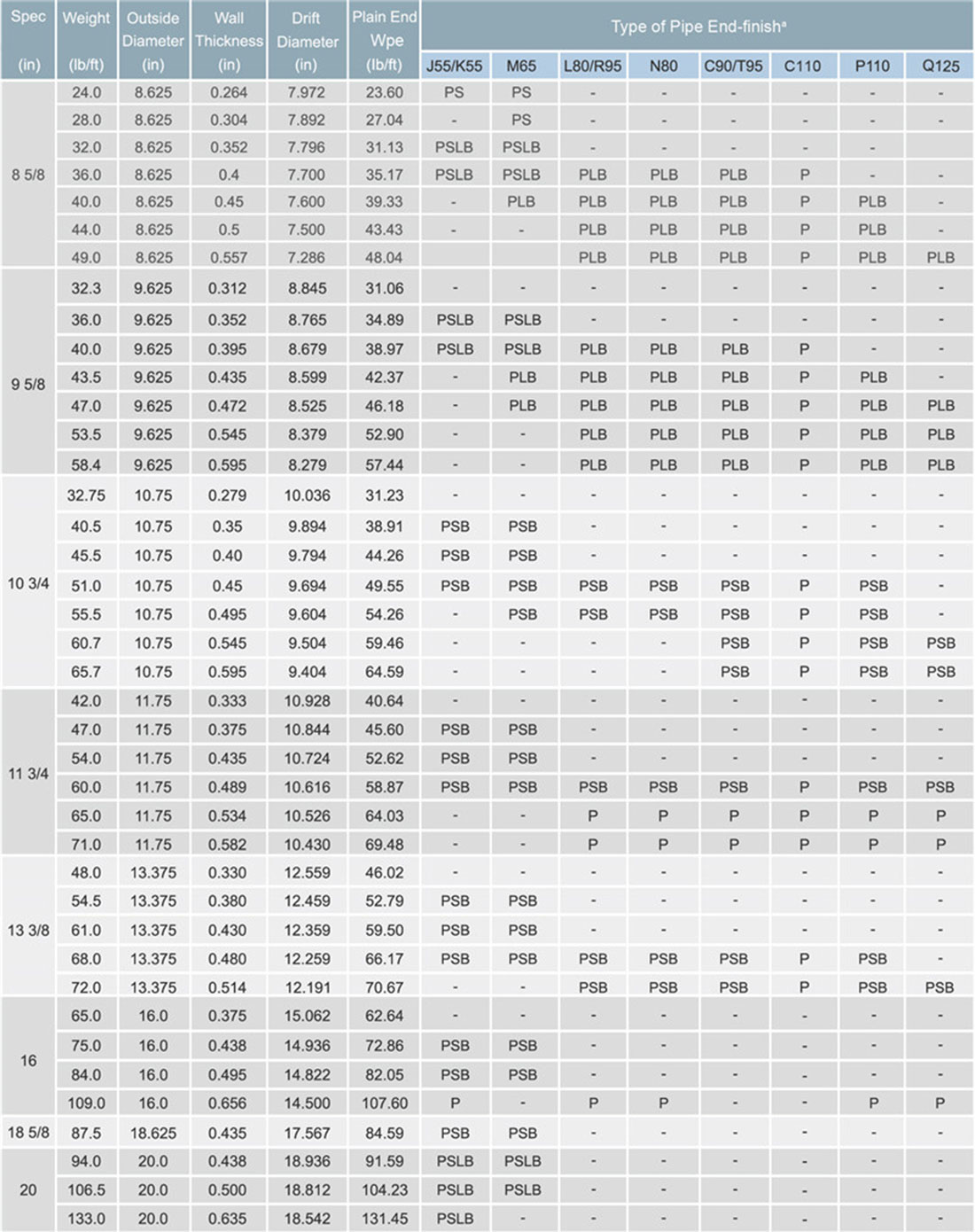

API Tubing

Once the casing is run and held in place with cement, production tubing is run into the oilwell.

Joints of tubing are connected together with couplings to make up a tubing string. Running tubing into an oilwell is much the same as for running in casing, but tubing is smaller in diameter and is removable.

The prodution string provides a continuous bore from the reservoir to the wellhead and together with the other components of the production string, produces oil and gas at the surface.

As opposed to casing, production tubing is designed to enable quick, efficient, and safe installation, removal and re-installation.

Oil and gas is also produced more effectively through tubing than through larger-diameter production casing.