Packer

Cementing Tools

Service Packer / Production Packer

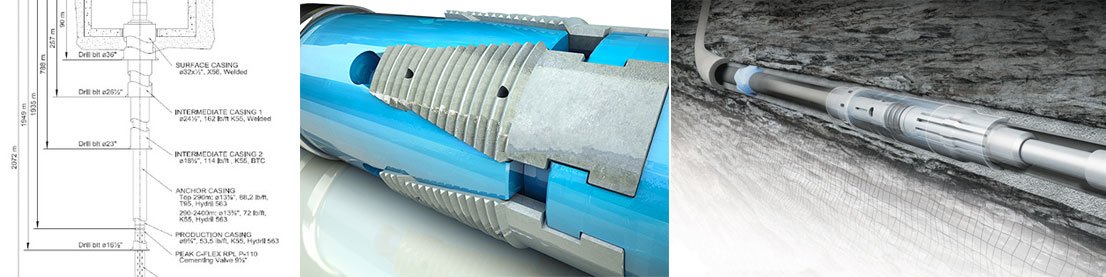

A packer is a standard component of the completion hardware of oil or gas wells used to provide a seal between the outside of the production tubing and the inside of the casing, liner, or wellbore wall.

It is a tool used to form an annular seal between two concentric strings of pipe or between the pipe and the wall of the open hole. A packer is usually set just above the producing zone to isolate the producing interval from the casing annulus or from producing zones elsewhere in the wellbore. Separates fluid types, protects against pressures and corrosion.

Based on their primary use, packers can be divided into two main categories: production packers and service packers. Production packers are those that remain in the well during well production. Service packers are used temporarily during well service activities such as cement squeezing, acidizing, fracturing and well testing.

Features

• Prevents premature setting of packer while running in hole.

• Hydraulically & mechanically increases the pressure applied to sealing elements maximizing seal against casing wall.

• Packer is locked in release position after unsetting preventing resetting or drag during retrieval.

• Ensures that all packer components are pulled back inside casing drift, reducing risk of drag or swabbing during retrieval.

Technical Data

| Type | K331-142 | K331-152 | K331-205 |

| Length (mm) | 4700 | 4760 | 4760 |

| Max OD (mm) | 142 | 152 | 205 |

| Min ID (mm) | 62 | 62 | 76 |

| Working Temperature (°C) | 350 | 350 | 350 |

| Working Pressure (MPa) | 17 | 17 | 17 |

| Sealing Temperature (°C) | 250 | 250 | 250 |