Cuttings Re-injection (CRI)

Cuttings Re-injection

Liquid receiving / Solids receiving & Pre-process

Skid Mounted & Trailer Mounted

Pre-process cuttings at rates 15m3/h

Achieve slurrification at rates 30m3/h, storage tank 1000bbl.

Achieve injection rates at 3.5m3/min

More than 10-years’ experience

The waste generated in the drilling process is transported to the slurry making system through the transmission equipment according to the drilling operation progress. The qualified slurry is injected into the selected reinjection well through a high-pressure pump. Real-time monitoring of various pressures, pump impulses, equipment parameters, etc. by data acquisition system to ensure smooth operation.

Wastes include solids (cuttings), liquid (mud, flow back, etc.). Solids and liquid are received separately to ensure no down-time.

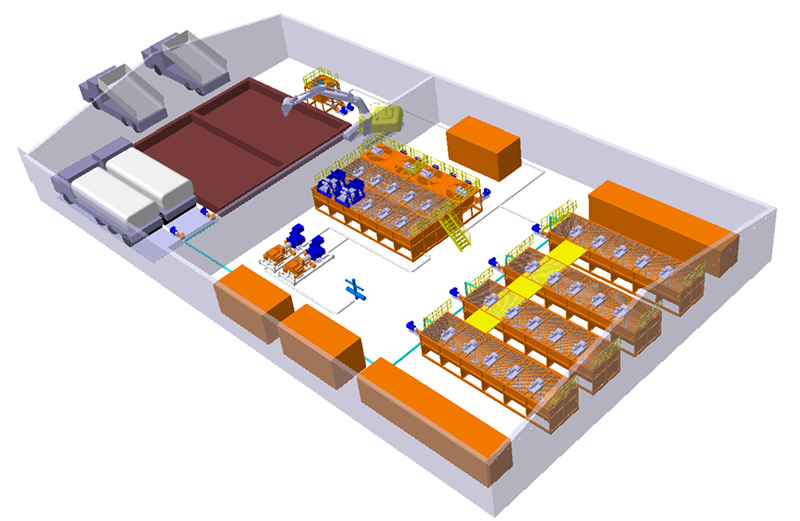

The Landa CRI system

Skid Mounted & Trailer Mounted Solids Injection Unit(CRI) are designed for customers.

Pre-process cuttings at rates 15m³/h, depending on the composition of the cuttings.

Achieve slurrification at rates 30m³/h, storage tank 1000bbl.

Achieve injection rates at 3.5m³/min (injection pressures up to 10,000 psi, motor drive)

Customized units with different control options (ABB, SIMENS, etc.) are designed to meet unique process needs and space requirements.

More than 10-years’ experience of wastes injection services.

More than 6-years’ experience for offshore cuttings reinjection.

Main components

Liquid receiving: Mud and watery wastes are directly pumped from mud pit to slurrification with advantages: fast speed, big capacity, low cost. And oil separation system (gun barrell) are available.

Solids receiving & Pre-process: The drilling cuttings are carried back to the slurrification through the process pipeline along with the medium of mixtures in coarse tank by using the centrifugal pump as power and utilizing the negative pressure generated by Venturi tube. The auger is mounted to the shakers of the rig to transfer all the cuttings to the pre- process system or Venturi system.

| Name | Power | Quantity |

| kW | ||

| Grinder | 55 | 2 pcs |

| Agitator | 15 | 2 pcs |

| Slurry making pump | 37 | 3 pcs |

| Separator | 2 | 1 pcs |

Slurrification: The cuttings enter the coarse tank grinding for 10-15 minutes. Observe the viscosity of the slurry in the tank, after that the slurry and cuttings will be sieved through a shaker to control the size of slurry granule.

| Name | Power kW | Volume m³ | Quantity |

| Treatment tank | / | 6 | 4 |

| Agitator | 15 | / | 4 |

| Slurry making pump | 37 | / | 8 |

| Shale Shaker | 3 | / | 3 |

Injection:The slurry is injected into the formation by the high pressure pump after it fills the storage tank. Record the well pressure, annulus pressure, pump rate, and motor parameters, etc. with the data acquisition system.

| Installed power | Working pressure MPa | Capacity | Remark |

| kW | m³/min | ||

| 800 | 70 | 2.1 | Triplex pump Type-800 |

| 800 | 55 | 2.7 | |

| 800 | 40 | 3.5 |

Installed power: 800kW

Maximum capacity: 3.5m³/min

Maximum reinjection pressure: 10,000psi

Motor drive

Adjustment pumping rate

Well & Pump parameter monitoring