BOP

Wellhead & Well Control Equipment

well control, casting, forging

BOP equipment (Blowout preventer) is used to control oil and gas wells to prevent blowouts. It is one of the most equipment for well control equipment. Finemade can supply different kinds of BOP, which works well in various conditions including low temperature, high temperature and high content of sulphur. Finemade provides many types of BOP for customers to choose. The bore hole size of our BOP products range from 65mm (2 9/16’’) to 762 (30’’), and the pressure grades range from 3.5MPa (500psi) to 140MPa (20000psi). The bodies are made by casting or forging with locking mechanism by manual or hydraulic operations. The rubber sealing parts used in our BOPs have the features of good resistance to low temperature, high temperature and hydrogen sulfide.

1. Annular BOP

Annual BOP consists of the body, upper housing, dust-proof ring, piston and packing element etc. It can seal all kinds of kelly, drill pipe, tool joint, drill collar, casing and cable, etc., and it can also completely shut off and seal the wellbore when there isn’t any drilling tool in the well hole. This BOP, when using accumulators, can allow the 18°/35° non-fine threaded tool joint pass through to carry out snubbing operation.

Technical Data

| Dimensions(outer diameter * height) | 1490*1250 mm |

| Weight | 6293kg |

| Bore size | 179.4mm (7 1/16’’) |

| Rated working pressure | 70Mpa (10000psi) |

| Closed string recommend hydraulic control working pressure | ≤10.5Mpa (≤1500psi) |

| Hydraulic control pipeline interfaces threads | NPT1 |

| Temperature Grade | T20 (-29°C- +121°C) |

| Open cavity volume(one) | 27L |

| Close cavity volume(one) | 36L |

| Sealing range | 0-179.4mm |

All sizes:

| Bore (inches) | 7-1/16 | 9 | 11 | 13-5/8 | 20-3/4 | 21-1/4 | ||||||

| Working Pressure (psi) | 3000 | 5000 | 3000 | 5000 | 3000 | 5000 | 10000 | 3000 | 5000 | 10000 | 3000 | 2000 |

| Operating Pressure (psi) | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Gallons to Close | 4.92 | 4.57 | 7.23 | 11.05 | 11 | 18.67 | 30.58 | 23.5 | 23.58 | 40.16 | 43.4 | 31.1 |

| Gallons to Open | 3.43 | 3.21 | 5.03 | 8.72 | 6.78 | 14.95 | 24.67 | 14.67 | 17.41 | 32.64 | 26.9 | 18.9 |

| Width (inches) | 29 | 29 | 35-1/2 | 40 | 39-7/8 | 44-3/4 | 57 | 46-3/8 | 50 | 64-1/2 | 54-1/8 | 52-3/4 |

| Height (inches), Studded Top, Flanged Bottom | 29-1/8 | 30-7/8 | 32-1/2 | 36-1/2 | 32-7/8 | 41-1/2 | 53 | 40-11/16 | 44-15/16 | 58-3/4 | 48-7/16 | 52-1/2 |

| Weight (lbs),Studded Top, Flanged Bottom | 2900 | 3175 | 4775 | 6800 | 5825 | 9550 | 23000 | 9100 | 13650 | 32475 | 14600 | 15100 |

| Ring Gasket | R-45 | R-46 | R-49 | R-50 | R-53 | R-54 | BX-158 | R-57 | BX-160 | BX-159 | R-74 | R-73 |

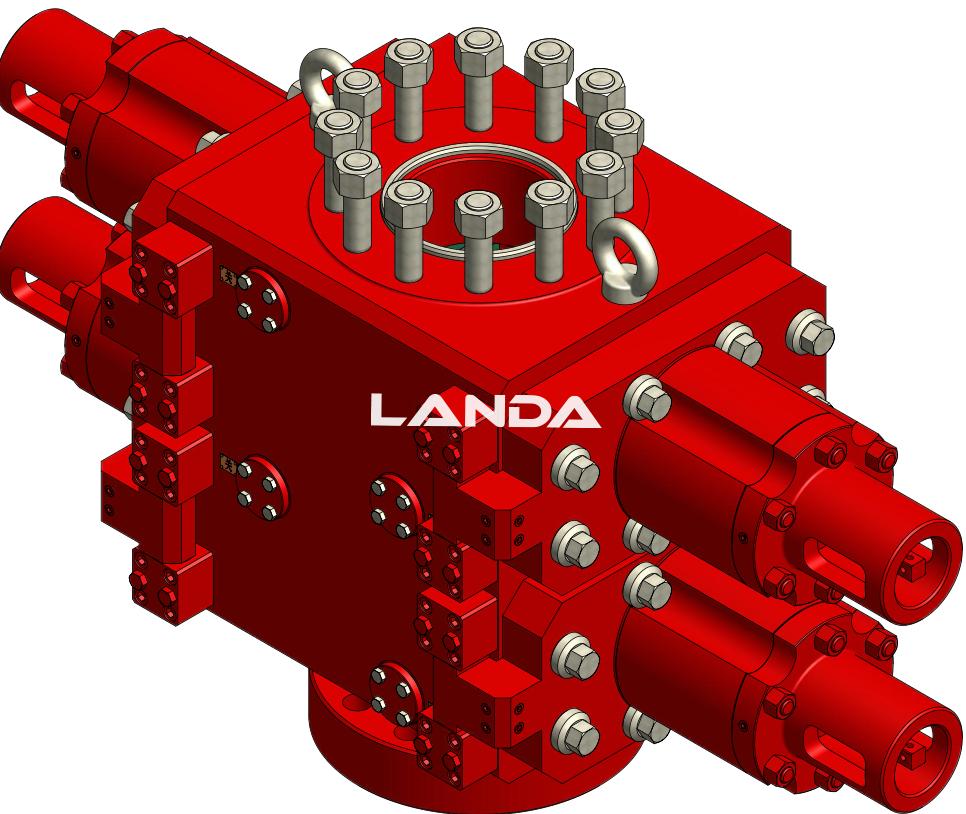

2. Ram BOP

The Ram BOP can be used to quickly seal the top of the well to prevent blowouts in workover and drilling operations. A ram blowout preventer consists of two halves of a cover for the well that are split down the middle.

Ram BOPs supplied by Finemade have several features. The main pressure-containing parts, such as the body, bonnet, etc., are made of high-strength and high-toughness alloy steel material. All parts are processed through proper heat treatment. The bonnet is connected to the body by hinge which can be opened manually to replace the ram assembly. The special designed floating ram sealing structure can reduce the resistance during the ram opening and closing, extend the ram duration time by reducing the packer wear etc., and can be dismantled easily.

API 16A Single Ram BOP

| Model | 2FZ18-21 | 2FZ18-35 |

| Rated working pressure (psi) | 3000 | 5000 |

| Nominal diameter (in) | 7 1/16 | 7 3/8 |

| Strength pressure test (psi) | 6000 | 7500 |

| Oil cylinder working pressure (psi) | 1200-1500 | 1200-1500 |

| Piston stroke (mm) | 100 | 100 |

| Metal temperature class | -29~121℃ | -29~121℃ |

| Nonmetal temp. class | -18~121℃ | -18~121℃ |

| Oil cylinder closed chamber volume | 2 x 1.75L | 2 x 1.75L |

| Oil cylinder open chamber volume | 2 x 1.50L | 2 x 1.50L |

| Ram closed interval(s) | <15 | <15 |

| Ram specification | 2 3/8” 2 7/8” 3 1/2” 4 1/2” blind ram | 2 3/8” 2 7/8” 3 1/2” 4 1/2” blind ram |

| Bolt quantity and diameter | 12-M30 x 3 x 210 | 12-M36 x 3 x 230 |

| Ring gasket | R45 | R46 |

| Dimension(mm) | 1350 x 380 x 638 | 1350 x 395 x 656 |

| Weight(lb) | 1717 | 1780 |

API 16A Double Ram BOP

Specification of LWP, LWS, SL/SLX Ram BOP

| Bore (inches) | 7-1/16 | 9 | 11 | 13-5/8 | 20-3/4 | 21-1/4 | ||||||

| Working Pressure (psi) | 5000 | 10000 | 3000 | 5000 | 3000 | 5000 | 10000 | 3000 | 5000 | 10000 | 3000 | 2000 |

| Length (inches) | 58-1/4 | 79 | 60 | 79-1/8 | 72-5/8 | 89-1/4 | 122-3/4 | 130-1/4 | 130-1/4 | 128-3/4 | 127-1/2 | 127-1/2 |

| Width (inches) | 21-1/2 | 30 | 21-1/2 | 23-1/16 | 25-15/16 | 28-3/4 | 38-9/16 | 40-3/4 | 40-3/4 | 43-1/16 | 41-1/4 | 40-7/8 |

| Height (inches), Single, Stud x Stud | 15 | 22-7/8 | 11-1/8 | 14-1/2 | 14-1/2 | 19-1/2 | 23-1/2 | 17-1/4 | 17-1/4 | 28 | 23-1/8 | 23-1/8 |

| Height (inches), Double, Stud x Stud | 26-3/4 | 36-5/8 | 22 | 29-1/2 | 29-3/8 | 33 | 40-7/8 | 34 | 34 | 46 | 49-1/4 | 44-7/16 |

| Weight (lbs), Single, Stud x Stud | 1385 | 5550 | 1170 | 2870 | 2116 | 4150 | 11100 | 8400 | 8800 | 13200 | 7448 | 7285 |

| Weight (lbs),Double, Stud x Stud | 2504 | 9900 | 2200 | 5750 | 4096 | 7725 | 20560 | 15350 | 15620 | 23400 | 14615 | 14455 |

| Gallons to Open | 1.18 | 2.34 | 0.68 | 2.27 | 1.45 | 2.62 | 7 | 4.46 | 4.46 | 10.52 | 4.46 | 4.46 |

| Gallons to Close | 1.45 | 2.72 | 0.77 | 2.58 | 1.74 | 2.98 | 9.45 | 5.44 | 5.44 | 10.58 | 5.07 | 5.07 |

| Closing Ratio | 5.45:1 | 7.11:1 | 4.5:1 | 5.57:1 | 5.45:1 | 5.57:1 | 7.11:1 | 5.54:1 | 5.54:1 | 7.11:1 | 5.57:1 | 5.57:1 |

Specification of Type U Style Ram BOP

| Bore (inches) | 7-1/16 | 11 | 13-5/8 | 20-3/4 | 21-1/4 | |||||||

| Working Pressure (psi) | 5000 | 10000 | 3000 | 5000 | 10000 | 15000 | 3000 | 5000 | 10000 | 15000 | 3000 | 2000 |

| Length (inches) | 74 | 74 | 95.25 | 96.25 | 96.25 | 124 | 112.13 | 112.13 | 114.13 | 139 | 143.69 | 143.69 |

| Width (inches) | 20.25 | 20.63 | 25.13 | 25.13 | 25.75 | 32 | 29.25 | 29.25 | 30.25 | 39.5 | 39.52 | 39.52 |

| Height (inches), Single, Flange x Flange | 27.5 | 30.56 | 29.06 | 34.31 | 35.69 | 44.81 | 31.31 | 33.81 | 41.69 | 53.69 | 40.56 | 37.9 |

| Height (inches), Double, Flange x Flange | 44.19 | 48.63 | 49.25 | 54.5 | 55.88 | 69.75 | 53.38 | 55.88 | 66.63 | 81.75 | 66.13 | 62.75 |

| Weight (lbs), Single, Flange x Flange | 2800 | 3550 | 5300 | 5600 | 6400 | 10300 | 7200 | 7700 | 10300 | 23700 | 13650 | 13250 |

| Weight (lbs), Double, Flange x Flange | 5200 | 6400 | 9900 | 10200 | 11300 | 18400 | 14300 | 14800 | 18400 | 43250 | 25550 | 25150 |

| Locking Screw Turns (Each End) | 18 | 18 | 27 | 27 | 27 | 32 | 32 | 32 | 32 | 45 | 46 | 46 |

| Gallons to Open | 1.3 | 1.3 | 3.4 | 3.4 | 3.4 | 5.7 | 5.5 | 5.5 | 5.5 | 10.4 | 8.1 | 9 |

| Gallons to Close | 1.3 | 1.3 | 3.5 | 3.5 | 3.5 | 5.8 | 5.8 | 5.8 | 5.8 | 10.6 | 8.7 | 8.7 |

| Closing Ratio | 6.9:1 | 6.9:1 | 7.3:1 | 7.3:1 | 7.3:1 | 9.8:1 | 7.0:1 | 7.0:1 | 7.0:1 | 10.6:1 | 7.0:1 | 7.0:1 |