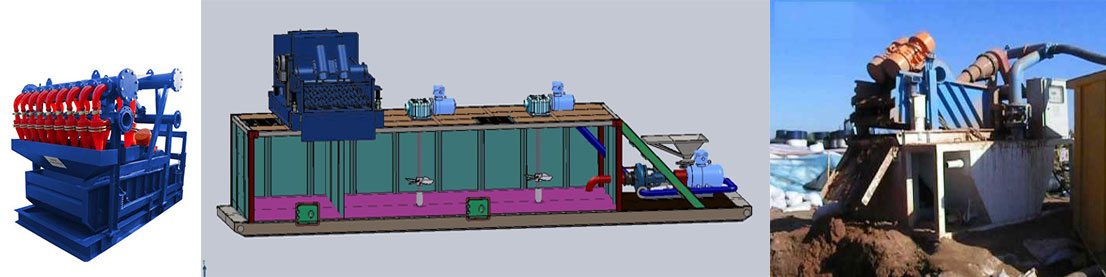

Mud Cleaner

Solid Control Equipment

Drilling Mud Cleaner/ Solids Control Equipment

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. Mud cleaner is a combination of desander and desilter and mounted over a shale shaker with a fine mesh screen. At the same time mud cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Finemade mud cleaner structure is compact, it occupy small space and the function is powerful. Mud cleaner is the ideal device of the second class and the third class solid control to treat the drilling mud.

Features

●Shale Shaker & Desander & Desilter 3 in one mud cleaner for 2nd and 3rd phase cleaning for small footprint.

●Both desander & desilter cone material is polyurethane (PU) for hard-wearing.

●Italy brand motor, standard brand is OLI, Martin or Itvibras motor as option

●Max G force reaches to 7.5G, G force adjustable depending on drilling mud conditions

●Heat treatment of shaker deck for steady working, Stainless Material for shaker deck bottom

●Heavy anti-corrosive painting on shaker service, 3 layer painting.

●Wedge type screen and hook strip screen both available to suit client requirement.

●Mechanical deck angle adjustment for steady and reliable performance.

●Standard options: IECEX, ATEX, UL, DGMS, CE, Gost.

●Top brand of electrical control panel, Siemens/Scheneider brand main components

●Composite material screen available for longer service life.

How To Choose a Mud Cleaner

Mud flow: Mud cleaner mud flow is decided by desander & desilter size and quantity.

The desander cone normally choose 10 inch size and desilter cone choose 4 inch size.

Once cone size is fixed, the mud flow will be fixed depending on cone quantity.

Bottom shaker: The bottom shaker will work to dry solids out of desander & desilter cone nozzle. The larger shaker deck will help for dry product and smaller shaker deck will save cost.

Electrical standard: Different area may require different standard like IECEX, ATEX, UL, DGMS, etc. Before order any equipment, please confirm electrical standard.

Customized design: Cone size and quantity can be customized design to reach different mud flow and performance.

Technical Data

| Model | MC50 | MC90 | MC 120 | MC 200 | MC 240 | MC 320 |

| Capacity | 50m³/h | 90m³/h | 120m³/h | 200m³/h | 240m³/h | 320m³/h |

| Desander Size | 8 inch | 10 inch | ||||

| Desander Qty | 1 Pcs | 2 Pcs | 3 Pcs | |||

| Desilter Size | 4 inch | |||||

| Desilter Qty | 4 pcs | 6 pcs | 8 pcs | 10 pcs | 12 pcs | 16 pcs |

| Work Pressure | 0.25~0.45 MPa | |||||

| Separate Point | 15μm~74μm | |||||

| Bottom Shaker | Model | Hunter Mini | Hunter D3 | Hunter MG4 | ||

| Vibration Mode | Linear Motion | |||||

| Vibrator Motor | 2×0.75Kw | 2×1.72Kw | 2×1.72Kw | |||

| G Force | ≤7.5G | |||||

| Deck Angle | 2° | -1 - +5° | ||||

| Screen Area | 1.35㎡ | 2.27㎡ | 2.73㎡ | |||

| Screen Panel | 2 Pcs | 3 Pcs | 4 Pcs | |||

| Dimension(mm) | 1650×1250×1750 | 1650×1250×1900 | 1650×1250×1900 | 2455×1850×2250 | 2455×1850×2250 | 2850×1800×2250 |

| Weight(Kg) | 1100 | 1600 | 1650 | 2100 | 2150 | 2350 |

| Remark | 4" cone =12~15m³/h, 8"cone=30~35m³/h,10"cone=90~120m³/h. It can be configured according to clients' demand | |||||