Desander

Solid Control Equipment

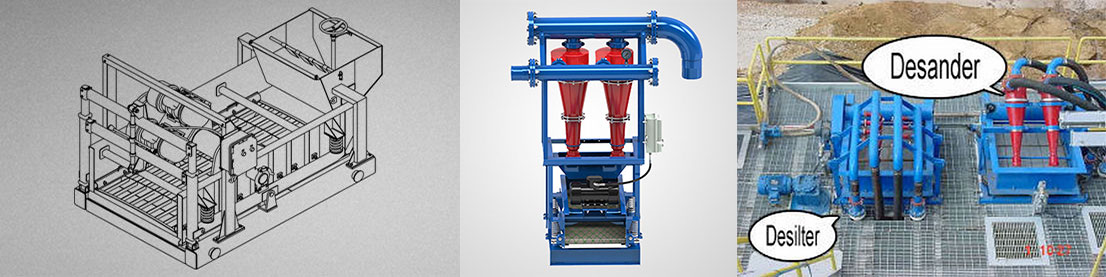

Mud Desander/Drilling Fluid Desander

A Desander is a hydroclone that is used to remove sand and silt from drilling fluids in a drilling rig. Hydroclones operate on the basis of centrifugal force such that the mud with smaller particles is returned to the active system while the larger particles are discarded. The usual size of a desander is 6 inches and above, however, the most common size is 10 inches.

A desander just like a desilter is a part of solid control equipment on drilling facilities. Its primary function is to remove sand particles which have a grain size of 50 to 70 microns. The installation position of desander is on the top of the mud tank following the shale shaker and the degasser, but before desilter. All solids that are not removed by a shale shaker are removed by the desander. Desanders do not have any moving parts hence the removal of sand and silt from the drilling fluid is done by the centrifugal force on the desander.

Working Principle

Desander Cyclones are pressure-driven separators that require a pressure drop across the unit to cause separation of the solids from the bulk phase (water, oil or gas, etc). The inlet stream (containing solids) enters the cyclone through a tangential Inlet Section under pressure, where it is forced into a spiral motion by the cyclone’s internal profile. The internal cone shape causes the spinning to accelerate, which generates high centrifugal forces, causing the denser solid particles to move to the outer wall of the Cyclone, while the Water/Oil/Gas is displaced to the central core.

Solids continue to spiral down along the outer wall of the conical section inside the Cyclone to the Outlet or Underflow, where they exit. It is typical to collect the solids in a closed underflow container or vessel, and periodically dump these solids.De-sanded Water/Oil/Gas in the central core section reverses direction and is forced out through the central Vortex Finder at the top of the Cyclone as the Overflow.

Types

√Without downstream drying shale shaker

√With ZS752 Series Mini Shale Shaker Screen Area:1.4m²

√With ZS703 Series 3 Panel Shale Shaker Screen Area:2.6m²

Features

●High Efficiency Solids Removal,

●Compact, small footprint,

●Cost effective protection against erosion damage,

●No moving parts and minimal maintenance,

●Highly consistent performance.

Technical Data

| Model | ZJ752F-1S/2S | ZJ703F-S2SF | ZJ703F-S3SF | WS-2SF/3SF | |

| Capacity | 120/240m³/h | 240m³/h | 360m³/h | 240/360m³/h | |

| (528/1056GPM) | (1056GPM) | (1584GPM) | (1056/1584GPM) | ||

| Desander Size(Inch) | 10″ | ||||

| Desander Qty | 1/2 Pc | 2 Pcs | 3 Pcs | 2/3 Pcs | |

| Working Pressure | 0.25~0.4Mpa | ||||

| Feeding Size | DN150 | ||||

| Output Size | DN200 | ||||

| Bottom Shaker Specs. | Shaker Model | ZS752F | ZS703F | N/A | |

| Vibration Mode | Linear Motion | ||||

| Vibration Motor | 2×0.75Kw | 2×1.72Kw | |||

| Screen Qty | 2 Panels | 3 Panels | |||

| Screen Size | 750×900mm | 700×1250mm | |||

| Screen Area | 1.35m² | 2.63m² | |||

| Adjust G Force | ≤7.1G(Adjustable) | ≤7.5G(Adjustable) | |||

| Vibration Amplitude | 3.92~5.62mm | 4.14~5.96mm | |||

| Deck Angle Range | +2° | -1~+5° | |||

| EX Standard | ExdIIBt4/IECEX/A-TEX | ||||

| Weight(Kg) | 1059/1114kg | 1835kg | 1924kg | 502/559kg | |

| Dimension(mm) | 1676×1754×1822 | 2419×2131×1656 | 2419×2135×2066 | 2177×1000×1901 | |